EIFS & Stucco Fastening 101: How to Choose and Install the Right Washers

Proper fastening is critical to the success and longevity of any EIFS (Exterior Insulation and Finish Systems) or stucco installation. Washers play a key role in securing insulation boards to substrates and ensuring that the system remains structurally sound and impact-resistant. Choosing the right type of washer—and installing it correctly—can help avoid costly callbacks and performance issues down the line.

Understanding the Different Types of Washers

There are several types of washers available, each suited to specific applications and substrate types. At Rescom Products, we offer:

– Imported 2″ EIFS Washers – Ideal for most residential and commercial installations. Cost-effective and compatible with most foam insulation panels.

– Domestic 2″ Washers – Made in the USA, these offer added durability and high manufacturing standards.

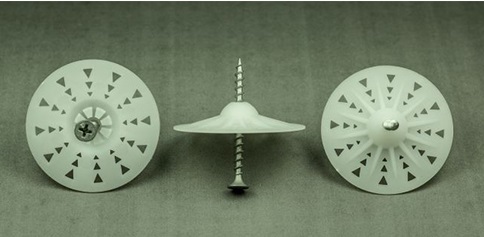

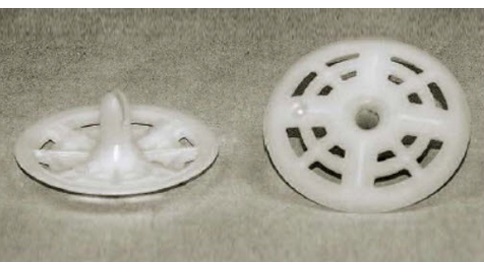

– 1¾″ Low-Profile Stucco Washers – Great for projects requiring a sleeker finish or where thickness tolerance is limited.

– Stemmed Washers – Designed for deeper penetration and stronger hold in high-wind zones or where additional embedment strength is needed.

Choosing between these depends on your wall assembly, the thickness of your insulation board, wind load requirements, and local code specifications.

Key Installation Tips for Washers and Fasteners

Once you’ve chosen the appropriate washer type, installation technique becomes crucial. Here are best practices to follow:

– Spacing: Space washers 12 to 16 inches apart, depending on board size and location. High-wind areas may require closer spacing or additional fasteners around openings.

– Driving Technique: Avoid over-driving, which can compress the foam board and reduce its insulating properties. Washers should be flush with the surface—not recessed or protruding.

– Alignment: Misaligned or angled fasteners can lead to bulging, cracking, or detachment. Always install at 90 degrees to the surface.

– Sequencing: After installing washers and fasteners, embed fiberglass mesh into a fresh base coat. This strengthens the entire assembly and prevents surface delamination.

Washer Selection by Application

Application Type | Recommended Washer Type

——————————|—————————–

Standard EIFS Wall System | 2″ Domestic or Imported Washers

Lightweight Panels or Foam | 1¾″ Low-Profile Washers

High Wind Zones / Coastal | Stemmed Washers + Close Spacing

Tight Tolerance Claddings | Flush, Low-Profile Options

Common Mistakes to Avoid

– Over-compression: Crushed insulation boards lose R-value and lead to finish failures.

– Loose fasteners: Lead to board movement and cracking under stress.

– Incorrect spacing: Can result in sagging boards and uneven finishes.

– Not pairing with compatible mesh and base coat: Even the best fastening won’t work if the rest of the system isn’t up to par.

Final Thoughts

Fasteners and washers may seem like a small part of an EIFS or stucco project, but they play a big role in the system’s integrity. By selecting the right type and following best practices during installation, you can ensure your wall assemblies are secure, durable, and built to last.

Explore Rescom Products’ full line of EIFS and stucco washers and get in touch if you need help choosing the right solution for your jobsite.